Keypoints

- Range consisting of 8 models

- Heating capacity from 53 to 365 kW

- Air flow rate from 4.800 to 33.000 m3/h

- High efficiency up to ~ 103%

- Versions available for indoor or outdoor installation

- Suitable for both ducted systems and direct diffusion via diffusion plenum (accessory)

- Versions available with increased static pressure for ducted diffusion systems

- Possibility to combine with two-stage or modulating forced draught burners for the maximum efficiency

- Gas fired

- Compliant with ErP 2021 regulation and the regional requirements of Piedmont, Lombardy, Emilia Romagna, DM 26 June 2015

- Versions available for tax deduction

Warm Air Heaters

TC-EKO Condensing gas-fired warm air heaters for inside installation

to 33.000

Product informations

Outer casing composed of sandwich panels, with external surface in pre-painted galvanized steel, insulation in glass wool and internal surface in galvanized steel with anti-radiation effect.

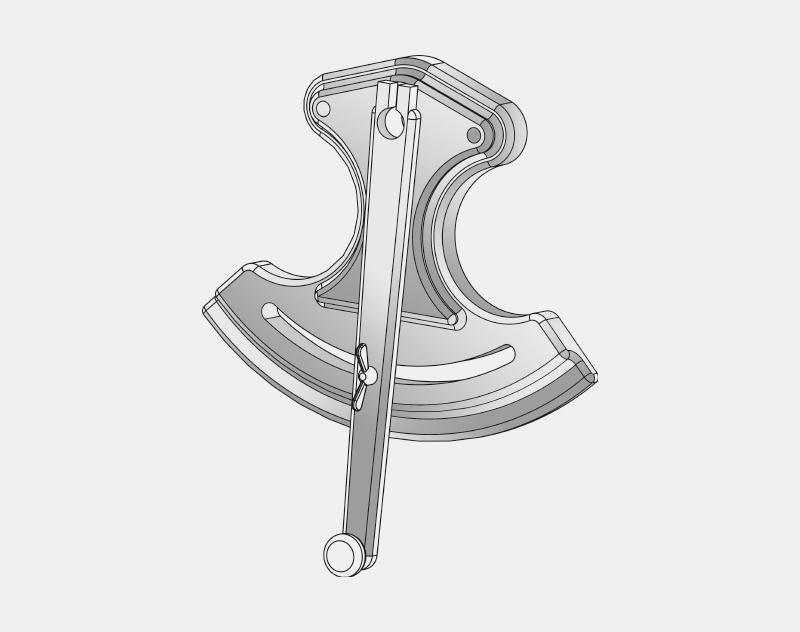

Three-pass heat exchanger with combustion chamber in AISI 430 stainless steel and tube bundle composed of two rows of smoke pipes, of which the second in AISI 304 stainless steel; complete with exhaust manifold with condensate discharge, inspection doors, chimney connection and plate for burner application.

Fan assembly with one or more high performance, low sound level centrifugal fans, complete with electric motor(s) and variable belt transmission(s).

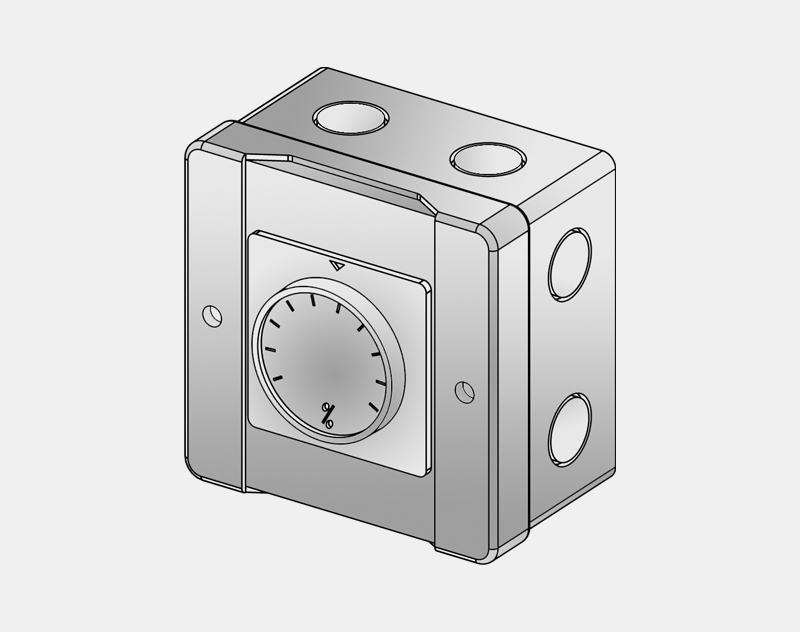

Electrical board for control and protection of the warm air heater designed for 400V 50Hz 3N power supply, complete with FAN, SAFETY (automatic reset) and LIMIT (manual reset).

|

Description |

U.M. |

TC-EKO 60 |

TC-EKO 75 |

TC-EKO 100 |

TC-EKO 150 |

|---|---|---|---|---|---|

|

Max nominal heating capacity input (burned) |

kW |

53,8 |

64,1 |

97,7 |

130,0 |

|

kcal/h |

46.270 |

55.130 |

84.030 |

111.800 |

|

|

Max USEFUL heating capacity output |

kW |

50,3 |

60,1 |

92,0 |

122,5 |

|

kcal/h |

42.270 |

51.660 |

79.150 |

105.320 |

|

|

Nominal air flow |

Nm3/h |

4.800 |

6.300 |

8.300 |

10.900 |

|

Useful static pressure |

Pa |

220 |

220 |

220 |

220 |

|

Description |

U.M. |

TC-EKO 200 |

TC-EKO 250 |

TC-EKO 350 |

TC-EKO 450 |

|---|---|---|---|---|---|

|

Max nominal heating capacity input (burned) |

kW |

170,8 |

212,4 |

295,3 |

365,0 |

|

kcal/h |

146.890 |

182.670 |

253.960 |

313.900 |

|

|

Max USEFUL heating capacity output |

kW |

161,4 |

200,9 |

280,8 |

347,1 |

|

kcal/h |

138.810 |

172.810 |

241.520 |

298.520 |

|

|

Nominal air flow |

Nm3/h |

14.000 |

19.000 |

25.000 |

33.000 |

|

Useful static pressure |

Pa |

220 |

220 |

220 |

220 |

|

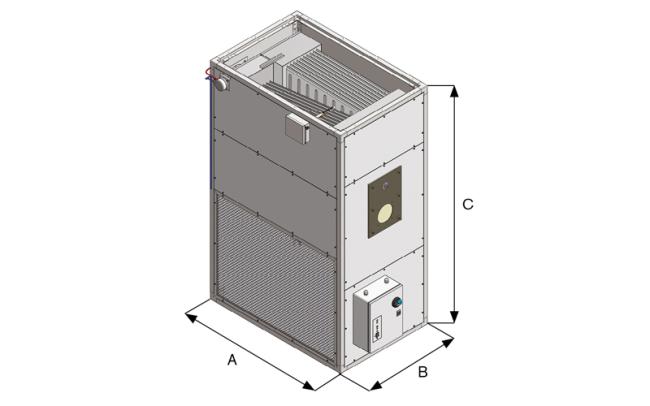

Model |

Dimensions mm |

Chimney Ø mm |

Weight kg |

Weight (with package) kg |

|||

|---|---|---|---|---|---|---|---|

|

A |

B |

C |

|||||

|

TC-EKO 60 |

950 |

650 |

1650 |

150 |

250 |

255 |

|

|

TC-EKO 75 |

950 |

650 |

1650 |

150 |

255 |

260 |

|

|

TC-EKO 100 |

1200 |

800 |

1900 |

180 |

340 |

350 |

|

|

TC-EKO 150 |

1200 |

800 |

1900 |

180 |

365 |

375 |

|

|

TC-EKO 200 |

1500 |

1000 |

2150 |

200 |

545 |

555 |

|

|

TC-EKO 250 |

1500 |

1000 |

2150 |

200 |

565 |

575 |

|

|

TC-EKO 350 |

1800 |

1250 |

2350 |

300 |

755 |

765 |

|

|

TC-EKO 450 |

1800 |

1250 |

2350 |

300 |

830 |

840 |

|

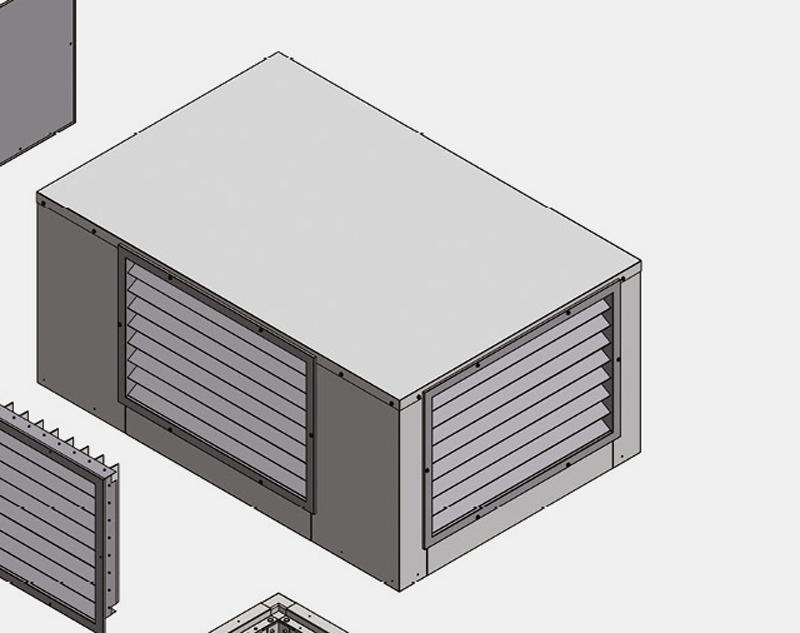

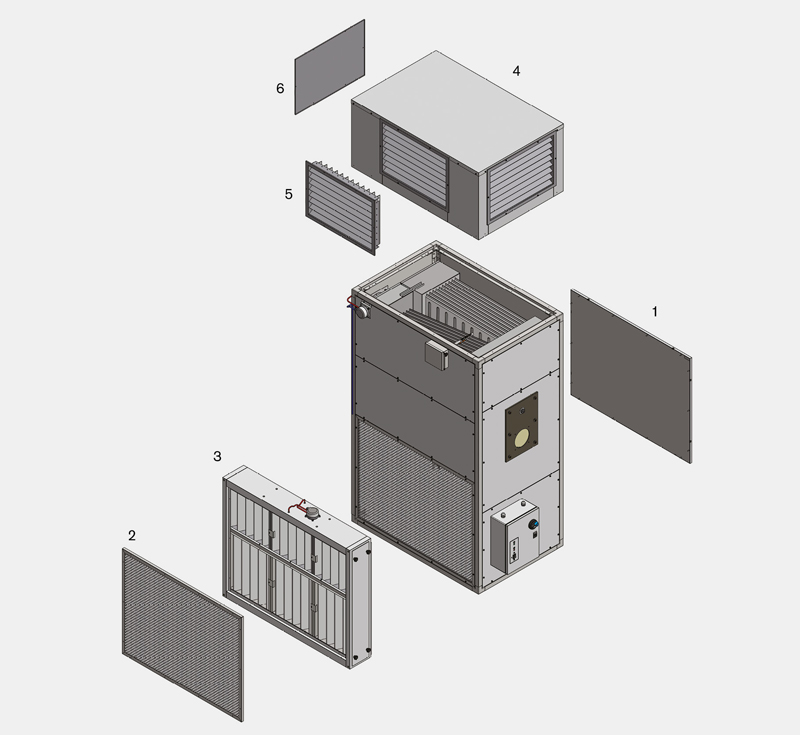

WARM AIR HEATER consisting of:

- Three-pass heat exchanger with combustion chamber in AISI 430 stainless steel and tube bundle composed of two rows of smoke pipes, of which the second in AISI 304 stainless steel; complete with exhaust manifold with condensate discharge, inspection doors, chimney connection and plate for burner application.

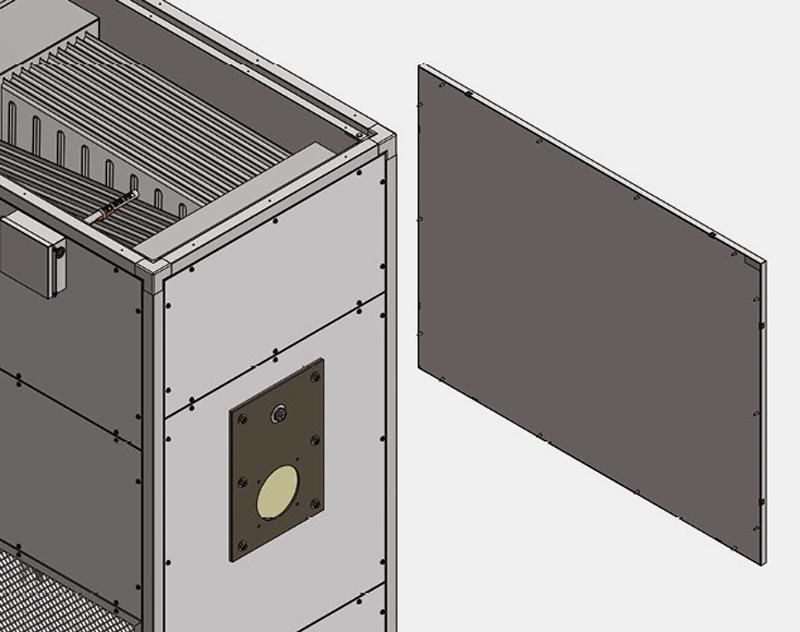

- Outer casing composed of sandwich panels, with external surface in pre-painted galvanized steel, insulation in glass wool and internal surface in galvanized steel with anti-radiation effect.

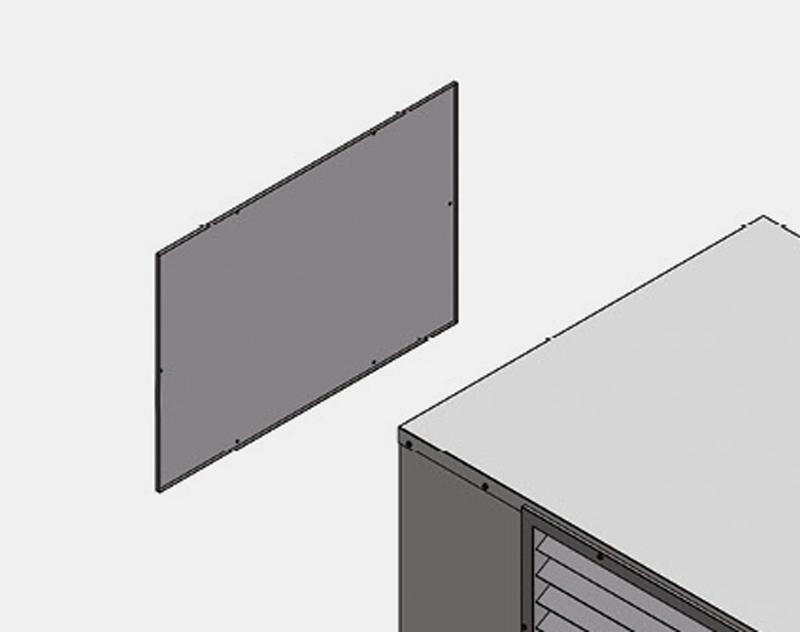

- Side panel for air inlet section.

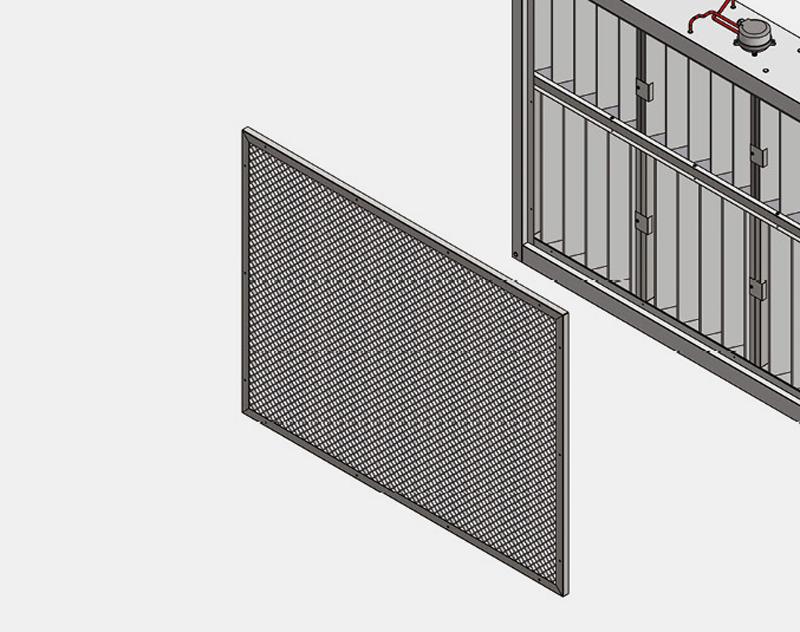

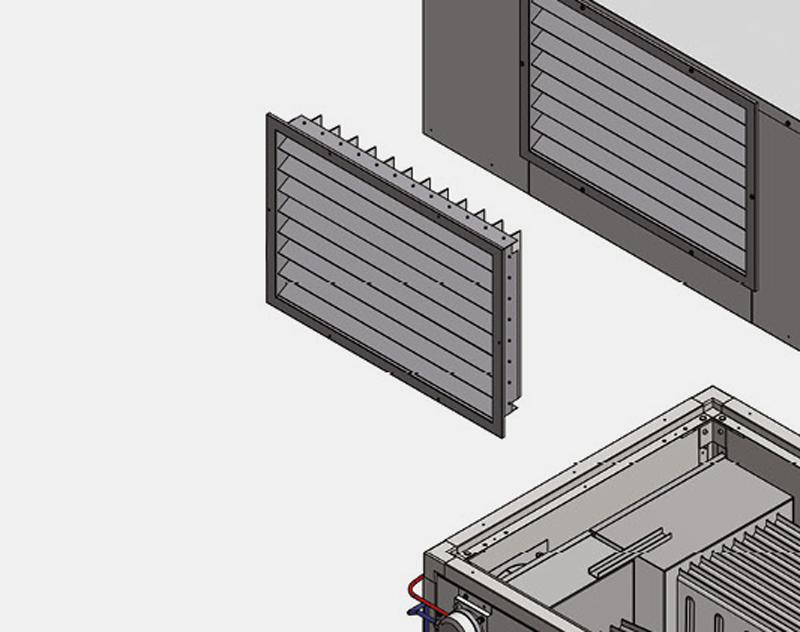

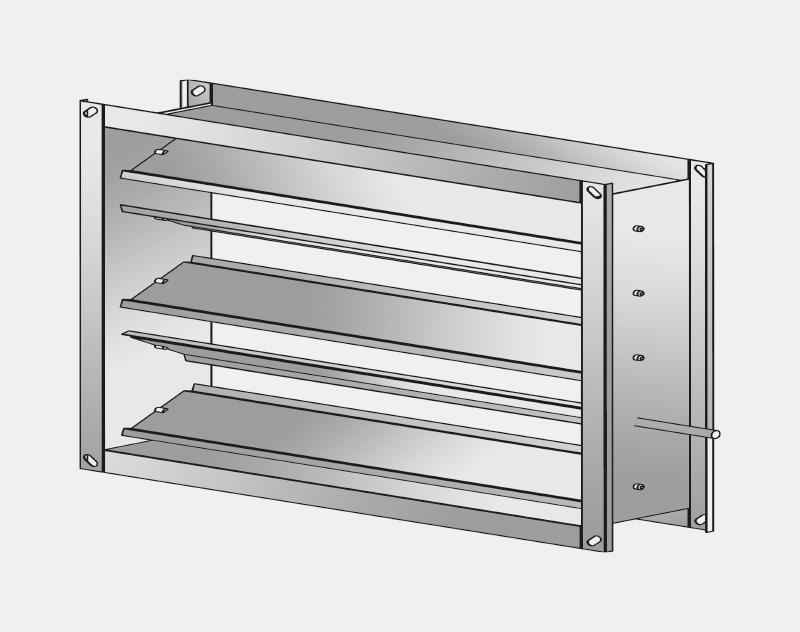

- Side grid for air inlet section.

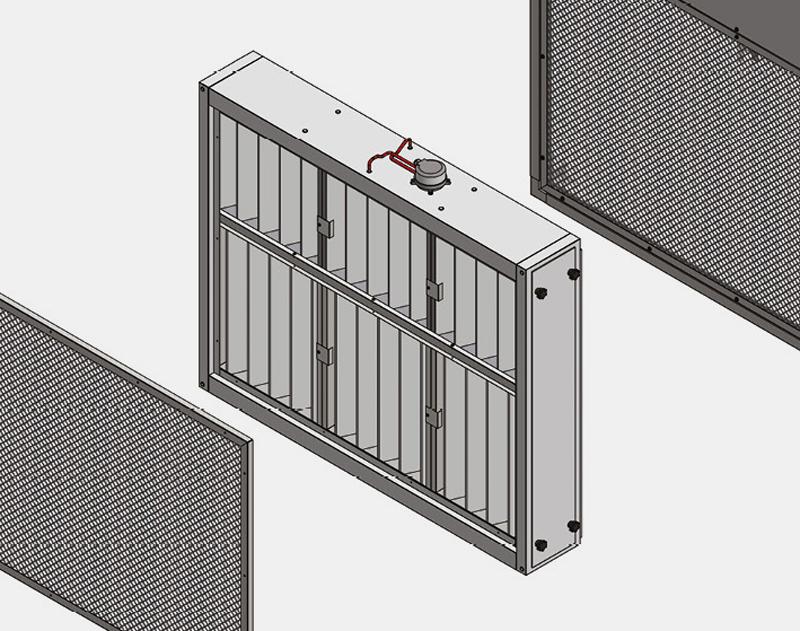

- Fan assembly with one or more high performance, low sound level centrifugal fans, complete with electric motor(s) and variable belt transmission(s).

- Electrical board for control and protection of the warm air heater designed for 400V 50Hz 3N power supply, complete with FAN, SAFETY (automatic reset) and LIMIT (manual reset).

PACKAGE: Warm air heaters are wrapped in plastic film and palletloaded.

-

Side panel

-

Side grid

-

Side air filter

-

Air diffusion plenum

-

Air delivery grill

-

Closing panel